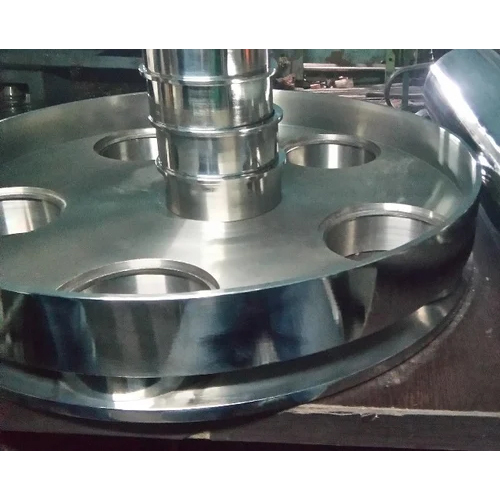

Pouch Packing Machine Part Disc Cup

Pouch Packing Machine Part Disc Cup Specification

- Surface Finish

- Polished

- Usage & Applications

- Packaging Industry

- Size

- Different available

- Material

- SS

- Voltage

- 220 Volt (v)

- Surface Treatment

- Coated

- Color

- Silver

- Warranty

- Yes

Pouch Packing Machine Part Disc Cup Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Main Domestic Market

- All India

About Pouch Packing Machine Part Disc Cup

The Pouch Packing Machine Part Disc Cup is an essential component for the packaging industry. Made of high-quality stainless steel, this product is available in different sizes and polished to a smooth, silver finish. This disc cup is designed to fit seamlessly into any pouch packing machine and is compatible with a voltage of 220V. This product is perfect for packaging various materials, including food items, pharmaceuticals, and consumer goods. Its durable construction ensures that it can withstand the rigors of daily use, and it comes with a warranty for added peace of mind.

| Filing Type | Cup Filler |

| Usage/Application | Packaging Industry |

| Voltage | 220 |

| Shape | Round |

| Capacity | All |

| Automation Grade | Manual |

FAQs of Pouch Packing Machine Part Disc Cup:

Q: What is the material used for this product?

A: The Pouch Packing Machine Part Disc Cup is made of high-quality stainless steel.Q: What is the size of this product?

A: This product is available in different sizes to fit various pouch packing machines.Q: What is the surface finish of this product?

A: The surface of this disc cup is polished to a smooth, silver finish.Q: Is this product compatible with 220V voltage?

A: Yes, this product is designed to be compatible with a voltage of 220V.Q: Does this product come with a warranty?

A: Yes, this disc cup comes with a warranty for added peace of mind.

-

The disc cup acts as a measuring device, scooping a specific volume of product to ensure accurate filling of each package.

-

It's suitable for products like grains, sugar, pulses, and powders that are uniform and free-flowing.

-

By changing the disc cup, operators can adjust the machine to fill different pouch sizes and product weights, making the machine adaptable to various needs.

-

Disc cups are typically made from high-quality stainless steel, such as SS304 grade.

-

The stainless steel construction ensures hygiene, is resistant to corrosion, and provides the durability needed for continuous operation in a packaging environment.

-

Often polished to a smooth surface, facilitating easy cleaning and preventing product residue buildup.

-

Some disc cups are "online adjustable," allowing for fine-tuning of the volume without stopping the machine.

-

They are designed to be easily integrated into the volumetric cup filler system of a pouch packing machine.

-

Available in different sizes to handle varying filling ranges and pouch volumes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+